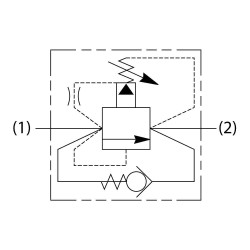

Pilot Operated Relief Valve with Free Reverse Check

Pilot operated relief valves are designed for continuous duty applications. Due to their stability and low pressure rise, the pilot operated relief is the best option for setting the pressure of a hydraulic system. The pilot operated valves will typically have a low pressure rise and will operate with less hydraulic noise. This particular model of spool type pilot operated valve has a reverse check. This allows flow to pass in the opposite direction, port 2 to 1. This may be advantageous in an anti-cavitation application, or where reverse flow needs to be accommodated.

Pilot operated relief valves are available is -08 to -20 size cavity configurations. This family of valves is best suited for continuous duty systems where the valve is asked to operate beyond any intermittent use. They can be used to maintain system pressure for long periods of time. Additionally, where systems may have large rates of change in flow, the pilot operated valves can accommodate these changes without excessive pressure rise or sometimes called pressure override. Due to the flow opening areas through the valve, these spool type valves will operate more quietly than a conventional direct acting valve. One must also consider the leakage component as the spool is, by design, going to pass a small leakage flow, whereas a direct acting valve does not pass significant flow until the cracking pressure is reached.

Typical applications are in mobile equipment, such as agricultural machines, aerial equipment, refuse vehicles, industrial power unit systems, mining equipment, and other heavy duty fluid power pressure control circuits.

Pilot operated relief valves are available is -08 to -20 size cavity configurations. This family of valves is best suited for continuous duty systems where the valve is asked to operate beyond any intermittent use. They can be used to maintain system pressure for long periods of time. Additionally, where systems may have large rates of change in flow, the pilot operated valves can accommodate these changes without excessive pressure rise or sometimes called pressure override. Due to the flow opening areas through the valve, these spool type valves will operate more quietly than a conventional direct acting valve. One must also consider the leakage component as the spool is, by design, going to pass a small leakage flow, whereas a direct acting valve does not pass significant flow until the cracking pressure is reached.

Typical applications are in mobile equipment, such as agricultural machines, aerial equipment, refuse vehicles, industrial power unit systems, mining equipment, and other heavy duty fluid power pressure control circuits.