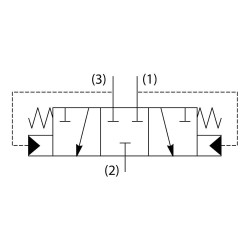

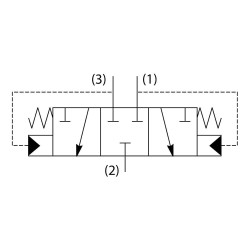

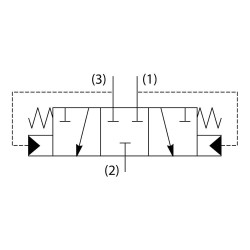

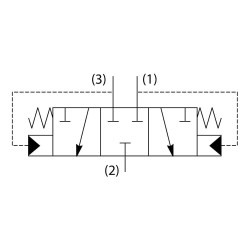

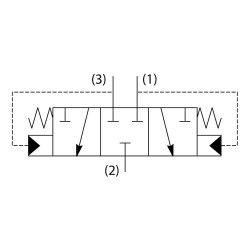

Cartridge Spool Type Shuttle Valves with All Ports Closed

In closed loop hydrostatic transmission systems, it is often necessary to bleed off some of the oil from the circuit and replace it with cool, clean oil from a charge replenishing pump. The hot oil is typically routed through a filter and cooler before returning to the reservoir. System designers use a hot oil shuttle valve to achieve this. Higher pressure fluid from the loop causes the shuttle valve to shift allowing oil from the low pressure side of the loop to be ported out the common port. These valves are usually used in conjunction with a relief valve. Parker’s K04C3 and K3A125 valves are high flow (15 gpm and 28 gpm respectively) with the K04C3 capable of 6000 psi and 5 switching pressures and K3A125 capable of 5000 psi and 2 switching pressures.