3 Way Flow Control Proportional Valves

Parker’s proportional flow control valves provide electronically variable flow control. Varying coil current will create a proportional flow out to an actuator allowing control of speed, acceleration, and deceleration. AC and DC coil options are available, along with a wide range of connection types. Current Controlled Pulse Width Modulation (PWM) valve drivers are preferred as they adjust for variations in coil temperature and also provide the ability to apply a dither frequency.

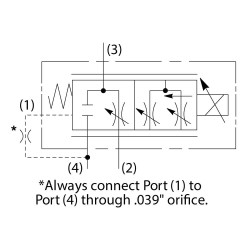

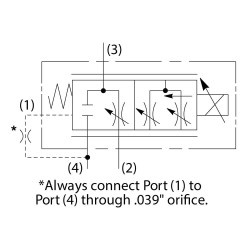

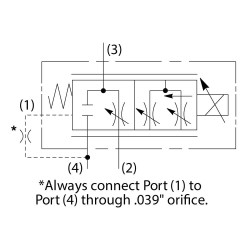

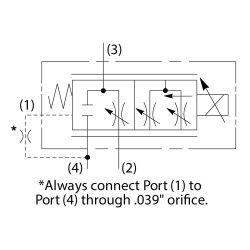

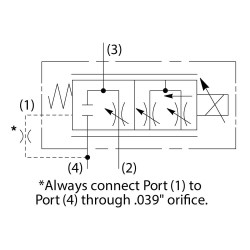

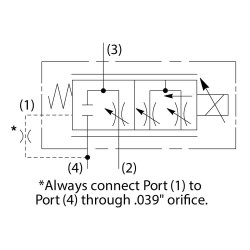

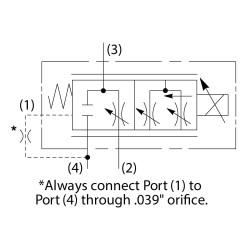

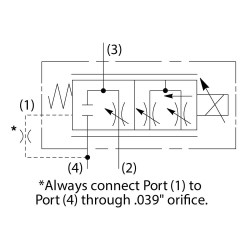

Priority Bypass is the last type of proportional flow control manufactured by Parker. Two sizes are available and the largest version is capable of flows up to 20 GPM (75 LPM.) Priority bypass flow controls are 3-way spool-type valves that consist of an inlet port, a priority port, and a bypass port. When no current is applied to the coil, all inlet flow exits the bypass port. As current is increased the spool shifts allowing a proportional amount of pressure compensated flow to the priority port while bypassing any remaining flow to the bypass port. Bypass flow is not allowed unless the priority ports has achieved the commanded proportional flow rate based on the input current. This allows for a priority of flow to one part of a circuit regardless of varying load conditions in both parts of the circuit. Typical priority applications include braking and steering.

Combined with Parker’s wide range of Coil options, the extensive proportional flow control offering allows for application specific solutions in the most demanding applications and markets including: Power Units, Oil and Gas, Material Handling, Construction, Drills, Presses, Mixers, Agriculture, Balers, Combines, Double Acting Cylinder Control, Bi-Direction Motor Control, Circuit Selectors, Skid-Steers, etc.

Priority Bypass is the last type of proportional flow control manufactured by Parker. Two sizes are available and the largest version is capable of flows up to 20 GPM (75 LPM.) Priority bypass flow controls are 3-way spool-type valves that consist of an inlet port, a priority port, and a bypass port. When no current is applied to the coil, all inlet flow exits the bypass port. As current is increased the spool shifts allowing a proportional amount of pressure compensated flow to the priority port while bypassing any remaining flow to the bypass port. Bypass flow is not allowed unless the priority ports has achieved the commanded proportional flow rate based on the input current. This allows for a priority of flow to one part of a circuit regardless of varying load conditions in both parts of the circuit. Typical priority applications include braking and steering.

Combined with Parker’s wide range of Coil options, the extensive proportional flow control offering allows for application specific solutions in the most demanding applications and markets including: Power Units, Oil and Gas, Material Handling, Construction, Drills, Presses, Mixers, Agriculture, Balers, Combines, Double Acting Cylinder Control, Bi-Direction Motor Control, Circuit Selectors, Skid-Steers, etc.