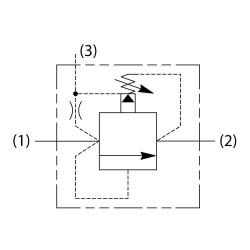

Pilot Operated Ventable Relief Valves

Ventable relief valves are pilot operated, spool type pressure controls. Like other pilot operated relief valves, the ventable relief has a main pilot spring chamber, and a bias spring chamber separated by a pilot orifice. The internal adjustment controls the main pilot spring setting. When pressure in the system builds above the setting of the main pilot setting, the pilot seat will lift allowing the spool to travel to the open position passing flow. What makes ventable relief valves unique is the valve offers an isolated vent chamber that is connected to the bias spring chamber. This allows for the valve to open at a lower pressure than the setting of the main spring.

The circuit designer has the ability to apply an external control valve or valves to set the operating pressure of the bias spring that must be overcome to allow the valve to open. This is an ideal solution in applications that may require variable pressure settings in normal operation.

One must consider the leakage component when applying any pilot operated spool type relief valve, as by design, the spool will pass a small leakage flow.

Typical applications are in mobile & industrial equipment, where multiple pressure settings may be required. Applications such as press or lift circuits where multiple pressure settings may be required.

• High flow capacity

• Full tank line back pressure capability

• Excellent flow pressure characteristics for consistent pressure setting

• Ideal for pump relief and remote control or unloading via vent (port 3)

• Integral 250 micron pilot flow filter

• Hardened working parts for maximum durability

• Adjustable and tamperproof versions available

• All external parts zinc plated

• Low override curve

• Ball-type pilot for added stability

• High accuracy - pilot operated design

• Hardened, precision ground parts for durability

• Compact size for reduced space requirements

• All external parts have yellow zinc dichromate. This coating is ideal for salt spray applications.

The circuit designer has the ability to apply an external control valve or valves to set the operating pressure of the bias spring that must be overcome to allow the valve to open. This is an ideal solution in applications that may require variable pressure settings in normal operation.

One must consider the leakage component when applying any pilot operated spool type relief valve, as by design, the spool will pass a small leakage flow.

Typical applications are in mobile & industrial equipment, where multiple pressure settings may be required. Applications such as press or lift circuits where multiple pressure settings may be required.

• High flow capacity

• Full tank line back pressure capability

• Excellent flow pressure characteristics for consistent pressure setting

• Ideal for pump relief and remote control or unloading via vent (port 3)

• Integral 250 micron pilot flow filter

• Hardened working parts for maximum durability

• Adjustable and tamperproof versions available

• All external parts zinc plated

• Low override curve

• Ball-type pilot for added stability

• High accuracy - pilot operated design

• Hardened, precision ground parts for durability

• Compact size for reduced space requirements

• All external parts have yellow zinc dichromate. This coating is ideal for salt spray applications.